Structure and Design from the Sketch to the prototype

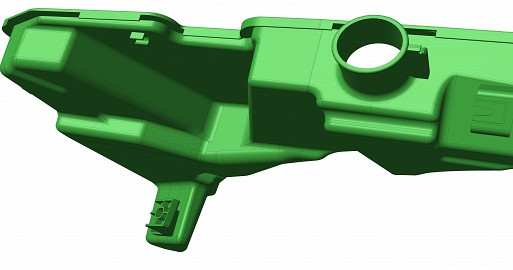

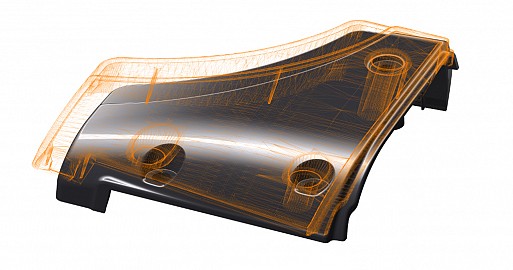

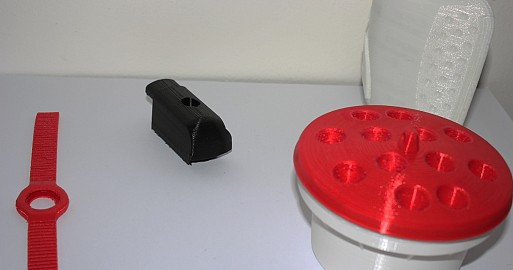

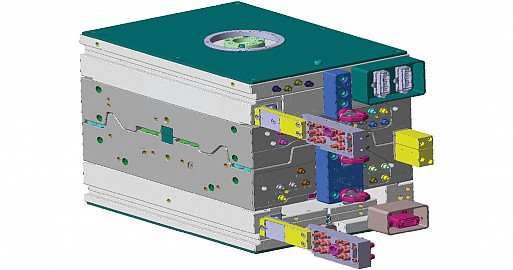

At Guipro Srl, the Technical Department handles the creation of new products or new product lines, also through the coordination and integration of skills and resources available in the company. It also takes care of the development and design of specific components with the aid of computer technology. In general it has a high degree of specific skills in various production sectors. It is a planning stage placed in between the Industrial designer and the production of the object, with the task of making the ideas and projects of the designer operational, starting from the reworking of the design, to the construction of the prototype. It is a technical-creative team capable of reworking and planning - with different techniques - the ideas and needs of the company, using advanced technologies as well as traditional ones.